Researchers have developed a new energy-efficient paint that resists heat, comes in any color, and should last for centuries. It is also the lightest paint created to date.

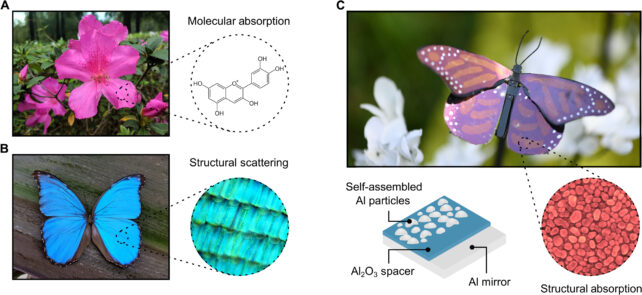

Inspired by butterfly wings, this paint is not made with pigment. Instead, the color is structurally generated by the arrangement of the nanoparticles. The team calls it “plasmonic coating.”

Based on their calculations, it will only take 1.4 kilograms (3 pounds) of plasmonic paint to cover a Boeing 747 – you’d need at least 454 kg (1,000 lb) of conventional commercial paint to do the same.

This means that it can significantly reduce the amount of greenhouse gases required for flight.

To be clear, this paint was only created in a lab, so we’re a long way from producing it collectively.

But the researchers have already made the paint in different colors using techniques that can be easily scaled up, and that’s what they’ll work on next.

One of the big drivers for bringing this coating to market is that it can also help keep structures cooler: Plasmonic coating structure reflects the entire infrared spectrum, so less heat is absorbed.

the say the researchers that surfaces under fresh paint remain 13 to 16 °C (25 to 30 °F) cooler than if covered with normal commercial paint.

More than 10 percent of all electricity in the United States goes to the use of air conditioners. says nanoscientist Debashis Chanda of the University of Central Florida, who led the team that created the paint.

“The difference in temperatures a plasmonic coating promises will lead to significant energy savings. Using less electricity for cooling will also reduce carbon dioxide emissions, and reduce global warming.”

Currently, pigment-based paints require specific molecules to build color, and these pigments in modern paints are usually synthesized artificially.

The electronic properties of each molecule control the amount of light absorbed, and thus the color of the paint that appears. This means that there must be a new pigment for every new paint color.

Instead, plasmonic coating uses nanoparticles of two colorless materials – aluminum and aluminum oxide. By arranging them in various ways above the anodized aluminum mirror, it is possible to control how light is scattered, reflected or absorbed.

A similar process is responsible for the rich color of butterfly wings.

The range of colors and shapes in the natural world [is] Stunning – from colorful flowers, birds and butterflies to underwater creatures like fish and cephalopods. Chanda says.

“Structural color serves as the primary mechanism for color generation in many very vivid species where the geometric arrangement of a normally colorless substance produces all colours. On the other hand, using [human-made] pigment, new molecules are needed for each existing color.

The structural color is what makes the coating so lightweight – at only 150 nanometers thick, the coating reaches the full color, making it Lightest paint ever.

In this research, the team created the structural coating using Electron beam evaporator which heats a substance at a highly controlled rate.

This controlled evaporation allows small clusters of aluminum nanoparticles to self-assemble—the aluminum atoms are more attracted to each other than to the oxide substrate they grow on, so they clump naturally.

By adjusting the pressure and temperature of the electron beam evaporator, the team can create structures that reflect different colors.

Crucially, this pressure- and temperature-controlled process ensures high reproducibility across large areas in a single step, reducing production cost and allowing large-scale manufacturing. The team writes in their paper.

The researchers also combined their structural color chips with a commercial binder, which means the paint will last for hundreds of years—at least, in theory.

“Natural color fades because the pigment loses its ability to absorb photons.” Chanda says.

“Here, we’re not limited to this phenomenon. Once we paint something with a structural color, it should stay for centuries.”

This is not the first new type of paint that promises some amazing properties. Many of you may have heard of Vantablack – one of the blackest paints in the world, which is able to absorb 99.96 percent of light.

Similar to plasmonic paint, this superior blackness is the result of tiny carbon nanotubes, and even blacker paints have been created based on the same method ever since.

There is also an ultra-white coating, which reflects 98.1 percent of all light and promises to greatly reduce air conditioning needs. But unlike plasmonic paint, ultra-white paint relies on pigments to reflect light, and Vantablack is currently only available in one color.

However, there is still a long way to go before we all customize our plasmonic paint colors and use just one small can to paint an entire house.

“Traditional pigment paint is made in large facilities where they can produce hundreds of gallons of paint.” Chanda says.

“At the moment, unless we go through a process of scaling up, it’s still expensive to produce in an academic lab.”

Research published in Science advances.

“Explorer. Unapologetic entrepreneur. Alcohol fanatic. Certified writer. Wannabe tv evangelist. Twitter fanatic. Student. Web scholar. Travel buff.”