Lathe machine tools is one of the key types of metalworking equipment widely used in machine building and other industries. This device is designed for mechanical processing of various parts made of metal, plastic, wood and other materials by removing chips from a rotating workpiece.

The basic principle of operation of the lathe is based on the rotation of the workpiece with a certain rotational speed and simultaneous movement of the cutting tool relative to this workpiece. In this case, unlike milling, where the tool rotates, in turning the workpiece itself rotates, and the tool, as a rule, is stationary.

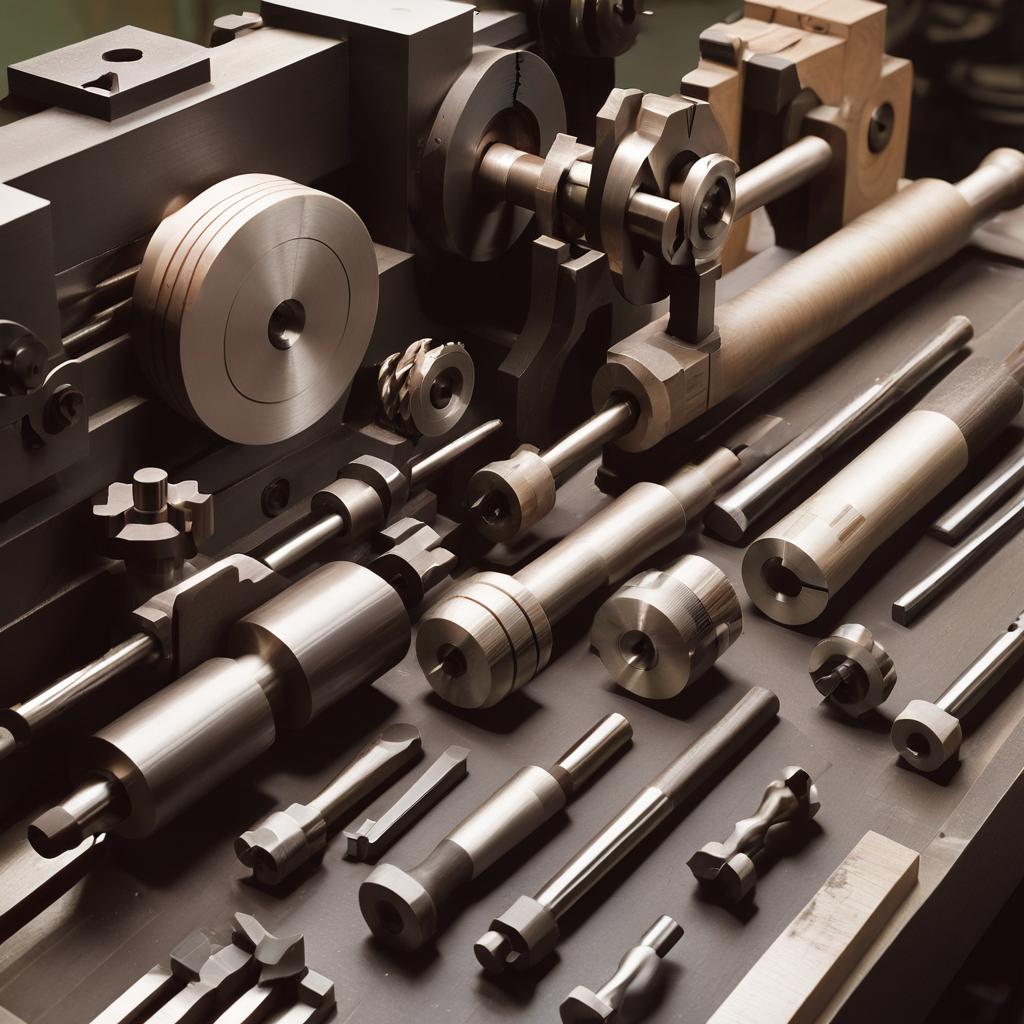

Tools used in the turning process

In the turning process, a number of different tools are used on the machine, the main ones being:

- Turning tools. This type of tool is a key tool in turning operations. Depending on the operations to be performed, the cutters can be sinker (for longitudinal machining), boring (for machining internal surfaces), undercutting (for machining faces) and cut-off cutters (for cutting off workpieces). There are also special threading cutters for thread cutting.

- Drills, reamers, countersinks. These tools are used for drilling holes, reaming, countersinking and other operations related to the processing of holes.

- Threading tools. These include taps for cutting internal threads and dies for cutting external threads.

The choice of specific tools depends on the material, shape and dimensions of the workpiece, as well as on the required accuracy and quality of machining. Competent use of these tools, along with the correct setting of cutting modes, is the key to high-performance and high-quality turning.

Live tooling lathe turret

The main features of live tooling lathe are that they are equipped with a turret that can not only turn the turning tools for turning, but also rotate additional tools such as drills, milling cutters, threaders, etc.

This makes it possible to perform not only turning operations on a lathe, but also drilling, milling, tapping and other operations without having to move the workpiece to separate machines.

Common turret lathe types

Today, there are three main types of turrets for CNC lathes: 1) VDI (“Verein Deutscher Ingenieure”, 2) BOT (Bolt-On Tool turret) and 3) BMT (Base Mount Tooling turret), as well as VDI/BOT combination turrets. Below we’ll take a look at these three basic types:

- VDI

In VDI turrets, the cutting tool is always mounted by means of special tooling blocks. The turret disk is equipped with cylindrical tool holes, with an internal retaining pin moved thanks to a screw on the turret surface.

- BOT

In BOT turrets, standard cutting tools for machining round workpieces are inserted directly into the turret without the use of toolholders, in special slots. The toolholding slots are milled on the front of the turret and the tool is clamped by a bar. Tools for machining complex profile holes are mounted by means of special tool blocks on the faces of the disk, in most cases with four bolts.

- BMT

Turrets of this type have incorporated the best from VDI and BOT turrets: they have the option of being equipped with driven tools (as in VDI), but with a motor integrated in the turret, which provides better traction and torque.

The cutting tools in BMT turrets are always mounted via toolholders. The tooling block slots are located only on the face of the turret, have 4 threaded holes for mounting screws, and a hole that can be used for both additional positioning and to accommodate the shank of the drive blocks.

“Web specialist. Lifelong zombie maven. Coffee ninja. Hipster-friendly analyst.”